-

-

Mon to Sat

08am - 09pm

-

WhatsApp

-

No. 188, East 3rd Road

Ruian, Zhejiang, China

Technical Data:

| Cups Specifications | 3-40 oz Paper cups |

| Forming size | Top: 60-100mm, Bottom: 40-75mm, Height: 60-180mm |

| Paper Specifications | 170-350g/㎡ |

| Papermaterial | Single/double PE/PLA coating |

| Production rate | 200-230 cup/min |

| Power supply | 380V 50Hz |

| General Power | 50Kw |

| Gas source | 0.6m³/min |

| Machine Weight | 7500Kg |

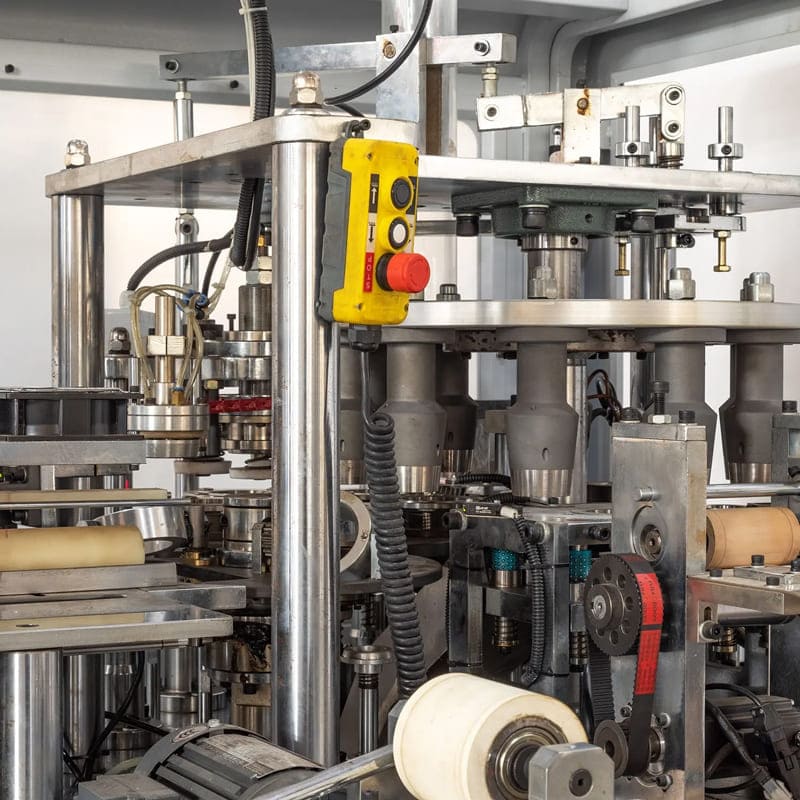

The RD-230A paper cup forming machine is at speed of 230 cupsper minute. The whole machine is controlled by PLC and servo.photoelectric tracking monitoring, and paper blank feeding controlby servo.

The machine can be produced the size of cup from 6ounces to 22 ounces by changing molds.RD-230A high speed automatic paper cup machine adopts advancedhorizontal structure to improve production stability and output.

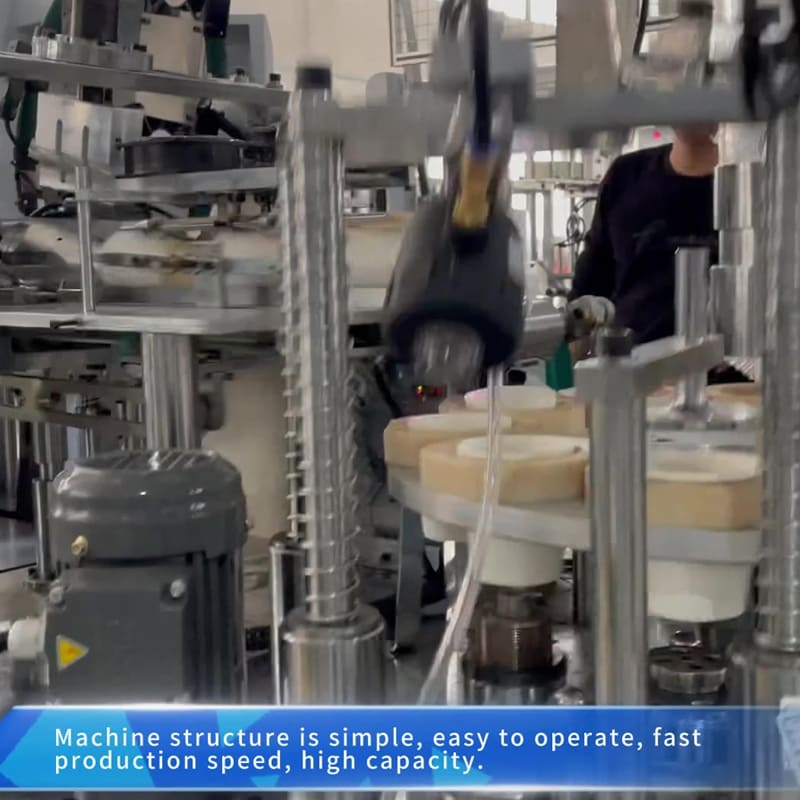

Model: RD-12/22-100A Automatic High Speed Paper Cup Forming Machine Customized 120-160 pcs/min 4-22oz Paper Cup Forming Machine

Technical Data:

| Cups Specifications | 4-16oz paper cup | 16-22oz paper cup |

|---|---|---|

| Cups material | Single or double PE Coated Paper | |

| Production rate | 120-160 pcs/min | |

| Paper Specifications | 190-380g/㎡ | |

| Electricity Supply | 380V/220V 50Hz | |

| General Power | 10 Kw | |

| Gas Source | 0.4m³/min | |

| Weight | 3000 Kg | |

| Packing Dimensions | 2750x1720x1800mm | |

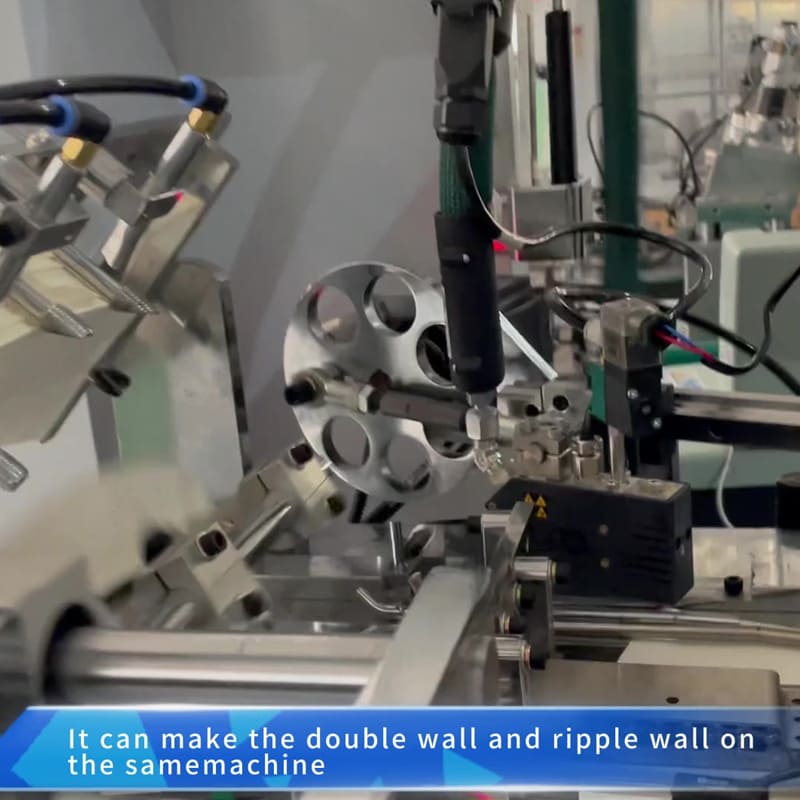

Model: RD-100T New Model High Speed Paper Double Wall Cup Forming Machine Customized 80-100 pcs/min 6-22oz Double Ripple Paper Cup Forming Machine

Technical Data:

| Cups Specifications | 6-16oz Double Cup | 16-22oz Double Cup |

|---|---|---|

| Production rate | 80-100 pcs/min | |

| Paper Specifications | 180-350g/㎡ | |

| Power Supply | 380v 50Hz / 220v 50Hz | |

| General Power | 6 Kw | |

| Gas Source | 0.3-0.5m³/min | |

| Weight | 2400 Kg | |

| Packing Dimensions | 2600x1360x1800 mm | 3200x1360x1800 mm (embossing) |

Paper cup machine sample cup specifications:

| Paper cup size | Dimensions (cm) | |||

|---|---|---|---|---|

| Ounce | Milliliter | Top Size | Btm Size | High |

| 2 oz | 60 ml | 5 | 3.5 | 4.8 |

| 3 oz | 90 ml | 5.5 | 3.7 | 5.6 |

| 4 oz | 120 ml | 6.2 | 4.6 | 6 |

| 5 oz | 150 ml | 6.9 | 5.2 | 7.1 |

| 6 oz | 180 ml | 7 | 4.9 | 8 |

| 7 oz | 210 ml | 7.3 | 5.3 | 7.9 |

| 8 oz | 240 ml | 8 | 5.6 | 9.2 |

| 9 oz | 270 ml | 7.6 | 5.3 | 9.5 |

| 10 oz | 300 ml | 9 | 5.8 | 9.9 |

| 12 oz | 355 ml | 9 | 5.9 | 11 |

| 16 oz | 475 ml | 9 | 6.1 | 13.5 |

| 20 oz | 590 ml | 9 | 6 | 15.8 |

| 24 oz | 710 ml | 9 | 6 | 18.3 |

| For reference only. please contact us for detailed specifications of the paper cup machine. | ||||

We not only have a paper cup machine, there are more related machines, such as: paper bowl machine, paper bucket machine, hidden tea cup hot sealing machine, coating machine, flexographic printing machine, die-cutting machine, paper plate machine, paper lunch box machine, paper cup detector machine, paper cup packaging machine and other machinery.

-

• Pre-sales service

• To provide a complete product introduction and specification, let customers understand what is their real need.

• Our specialists will provide design and consultation, recommend the most appropriate products to customers’ actually need.

-

• Sales service

• Provides full technical support. According to the chosen model, assists customers to have an optimized and economic production plan.

• Free training for installation, operation and maintenance, assists to set up a service program.

• A strict supply chain management, process control and comply with contracts to make product delivery on time.

-

• After-sales service

• Under warranty period, customers will have five years freemechanic parts replacement; Ruida Machinery will provide service and original spare parts supply forall productsin their life time as a promise.

• Provides installation supervising, fine tune assisting, operation and maintenance training.

-

Call anytime

-

Send email

-

Visit office

No. 188, East 3rd Road